Welcome to SAPTHAGIRI PACKAGINGS

We live in a wonderful age of multiple technical developments. “ MULTI” is becoming synonymous to latest developments

and means optimum utilization of re-sources – Flexible activities and materials, used in combination to minimize cost,

add versality and at the same time improve quality. Multi is closely associated with money. Market demands multiple properties,

multi services at the same money or with less money. Plastic industry is not exception to that.

Uses of plastic films are cost

and quality consicous and have requirement of multi layer films specific for their end use. Technical achievement in both

polymerization and processing technologies allow the processor to manufacture to this variety of muti layer film with added

functional and aesthetic characteristic and at the same time at reduced cost.

Quality Control Lab Facilities

- * GC Test - for solvent retention testing.

- * Universal Testing Machine (UTM) for Bond Strength, Seal Strength, Tensile Strength & Elongation.

- * Hot Air Oven.

- * Coefficient of Friction (COF) Testing Machine (Static & Kinetic).

- * Bursting Strength Tester.

- * COBB Tester - for Paper Water Absorption Rate.

- * Dart Impact Tester

- * Ford Cup (B4 TYPE) for Viscocity of inks & adhesives.

- Our Services Are

- 1. Categories of Machins

- 2. Products

- 3. Laminated Roll/ Laminated Pouches

- 4. Others

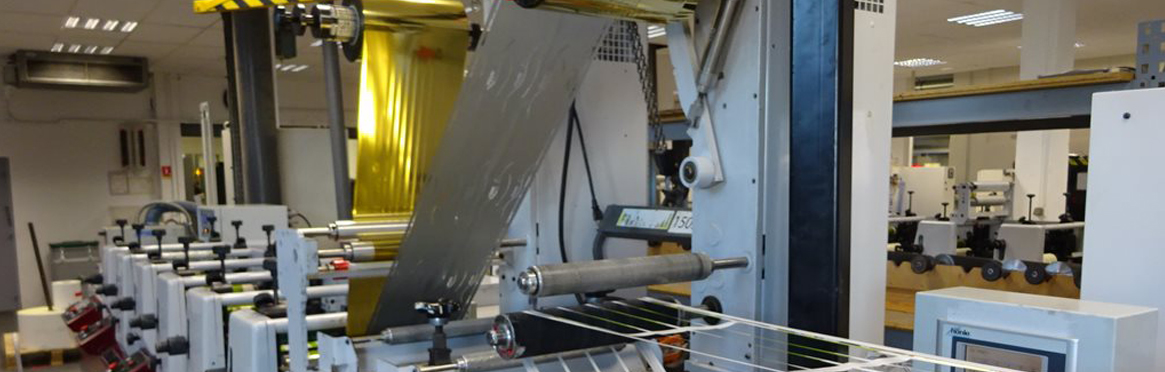

Machine Types

1. Three Layer Film Extruder of KABRA make

2. Eight Colour Roto Gravure Printing Machine

3. Slitting Machine

4. Carona Discharge Treatment Plant

5. Dry Lamination machine

6. Full Quality control equipments

Products

Our latest flexible packaging materials technology comprises of the following conversion facilities:

• Food Packing

• Seeds & Fertilisers

• Liquid Packing

• Health Care

• Confectionery & Biscuit

• Tea & Coffee

• Frozen Foods

• Snacks

• Copier wrappers

• Groceries

• Milk Film

• Edible Oil and Vanaspathi

• Cement paint

• Detergents

• Atta / Rava / Maida

• Salt

• Trash bags

• Strech wrap

Laminated rolls and laminated pouches are made in various combinations of pet / bopp / poly films etc to suit your products and are manufactured using advanced lamination process to achieve optimum result at most economical costs. Pouches can be: zipper, gusset, pillow, center seal, stand up, 3 side seal, 5 side seal D- Pouch etc.

Laminated Roll/ Laminated Pouches:

• Food and confectionery products: Tea, Coffee, Spices, Edibles Oils, Jam, Ketchups, Jelly, Pickles, Biscuits, Chips, Namkeens, Ice-creams, Sea Foods, etc.

• Cosmetics and toiletries: Hair Oil, Shampoo, Conditioner, Powder, etc.

• Detergent products and soap products

• Pharmaceutical products

• Engineering products

High Performance

We are one of the high quality flexible packaging materials manufacturer in India. Printed laminates made by Rotogravure process, printed in upto eight colours depending on the barrier properties and shelf life of the product required. Multi layer laminates of various combinations ranging single layer to five layers such as Pet -Poly, Pet -Metpet -Poly, Bopp-Extrusion laminate -Metpet -Poly, Bopp -Bopp, Pet -Bopp etc., to pack products such as biscuits, candies, chocolates, potato chips, snack foods, tea, coffee, spices, sugar, salt, noodles, cereals, dry fruits, rice, pesticides, liquor, oils, fertilizers, engineering products, etc.

Similarly tests are carried out on all incoming raw materials to ensure that the products are clean, hygenic and defect-free. Checks are done at stages of production to ensure confirmity to customers specifications.